Introducing Our Revolutionary Hydraulic Lift Platform

Streamline Your Operations Today!

Click the table of contents to find what you're interested in →

What is a hydraulic lift platform?

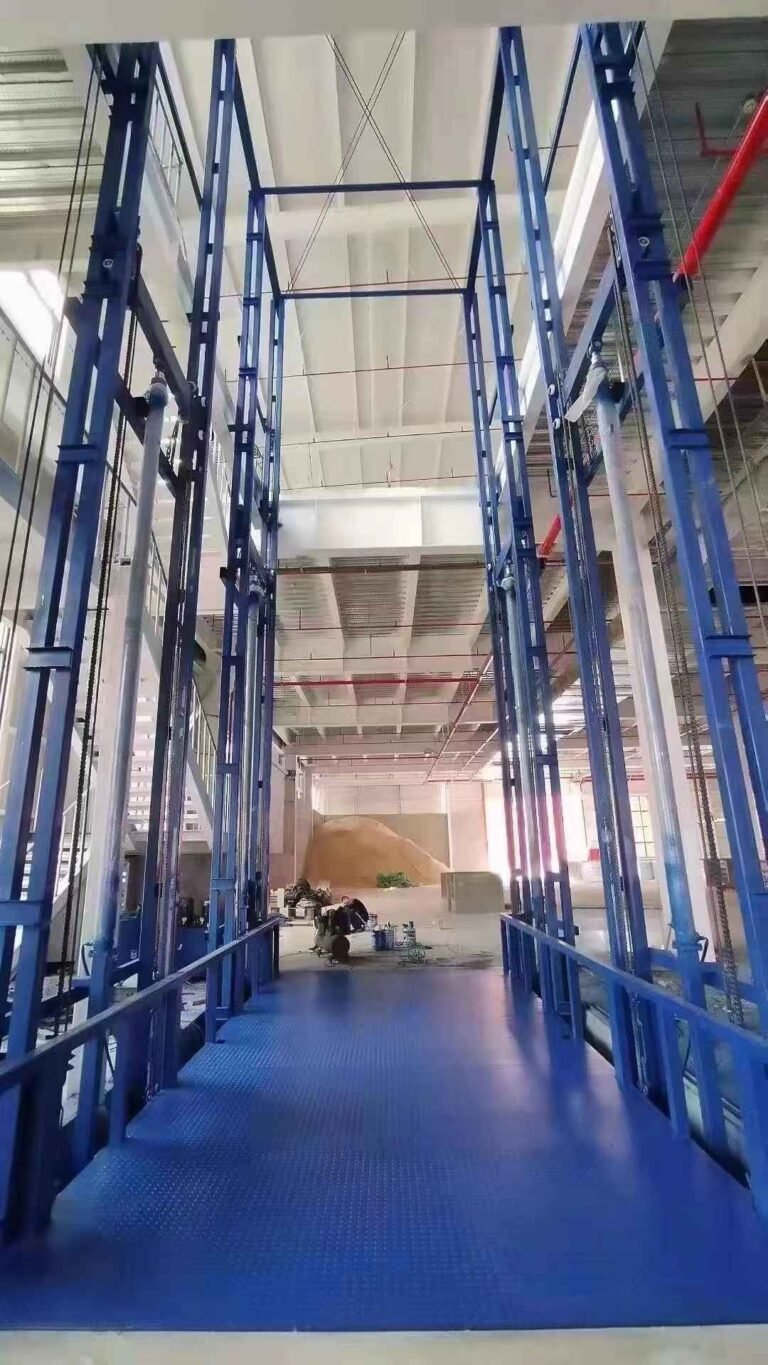

A hydraulic lifting platform, also known as a goods lift or freight elevator, is a vertical transportation system designed to transport heavy goods or materials between different floors or floors of a building.

It adopts electro-hydraulic lifting. When working, the platform moves up and down in the vertical direction along the guide rail. When rising, use the electric motor to drive the hydraulic oil pump to rotate at a high speed, pump the hydraulic oil into the hydraulic cylinder through the action of the hydraulic oil pump, and the high-pressure hydraulic oil acts on the piston rod of the oil cylinder to make it extend upwards and push the sprocket frame to move upward. The upper sprocket drives the chain to move, and the bottom end of the chain is connected to the cargo platform, thereby driving the lifting operation platform to rise. When the platform is descending, open the descending electromagnetic oil return valve through electrical control, and under the action of the platform and the gravity of the cargo itself, the platform will naturally descend, so that the motor does not need to run.

Uses of a hydraulic lift platform

The hydraulic lifting platform can be installed in various buildings, including office buildings, warehouses, retail stores, factories, stations, airports, schools, hospitals, hotels and other places, and it is the most economical multi-storey cargo vertical transportation equipment. They are typically used in industrial and commercial settings where large or heavy items need to be moved between floors, and where the use of stairs or manual labor is impractical.

Advantages of Using a hydraulic lift platform

Less civil work requirement

The height of the platform itself is low, the minimum can be 80mm, which is especially suitable for places where the pit cannot be dug or the pit cannot be dug deep ( pit depth is 150mm~ 300mm);

The force direction of the platform is in the vertical direction, the installation does not require a shaft, and no need be with machine room.

There is no special requirement for the height of the top floor。

It can be customized according to the site environment.

High lifting height+ Capacity, Less power

The lifting height of hydraulic lift platform can be >20 meters.

At present, the maximum loading capacity of our lifting platforms can reach 30 tons, and various lifting platforms can be customized according to the customer’s requirements.

When the hydraulic lift platform goes down, it is driven by the pressure generated by its own weight, without using a motor to drive, thereby reducing the power consumption of the equipment and achieving substantial energy saving.

The structure of the hydraulic lifting platform

Product introduction

.

Guide rail

It is used for guidance to ensure that the lifting platform moves up and down along the direction of the guide rail to prevent the platform from deviation. At present, the guide rail is generally made of Q235B channel steel, square steel tube or H-shaped steel.

Platform

The platform is the place where goods are stacked, generally made of rectangular steel tube or channel steel, and covered with high-strength anti-skid checkered steel plate.

Guide plate

It is used to fasten the guide rail wheels and side wheels.

Hydraulic system

The hydraulic system mainly consists of modular hydraulic pump stations, oil cylinders and hydraulic pipelines. The oil cylinder is to drive the sprocket frame. Modular hydraulic pump station is composed of electric motor, gear pump, overflow valve, check valve and electromagnetic reversing valve, which is the core of the hydraulic system. Hydraulic pipelines are channels through which hydraulic oil flows.

Electrical control box

The electrical control box mainly controls the rise and fall of the lifting platform, and cooperates with other electrical components for protection.

Sprocket frame and Chain

The sprocket frame is the part that fixes the sprocket. It is connected to the oil cylinder and is the transmission mechanism of the lifting platform. The chain is an important part of the transmission system of the lifting platform.

Safety Tips for using a hydraulic lifting platform.

Product introduction

.

Tip One

Should arrange special personnel to operate the lifting operation platform, and formulate the details of the use of the lifting operation platform and safety precautions, and hang it in an obvious position.

Tip Two

When the lifting platform is working, it must be equipped with professional drivers and operators, and must undergo special training and pass the examination before taking up the job.

Tip Three

It is strictly forbidden to carry people on the cargo lifting platform.

Tip four

Before daily work, the operator must carefully check whether the electrical system, hydraulic and mechanical systems of the platform are normal, check the working range of the lifting platform, and remove obstacles that hinder the operation of the lifting platform. Let the platform run up and down with no load several times to check whether there are any faults and abnormal phenomena. It is also necessary to pay attention to whether there is an obvious abnormal gap in the accuracy of leveling.

Tip Five

It is strictly forbidden for the lifting platform to work when the door of the protective fence is open. In case of special circumstances during the operation of the lifting platform, the emergency stop switch can be used to stop the platform.

Tip Six

The operator is strictly prohibited from wiping, lubricating or repairing the platform while operating the platform.

Tip Seven

When the platform breaks down or fails to work normally, the maintenance personnel should be notified immediately to repair it. If it is found to be dangerous or may cause personal and mechanical failures, it should stop using it immediately, cut off the main power supply at once, and report to the management department.

Tip Eight

The operator should regularly add lubricating grease every week and check the line regularly to avoid wear and tear.

Tip Nine

The operator should be responsible for supervising that the items transported by the platform are distributed as evenly as possible on the platform to prevent partial loading and prohibit overloading.

6 Tips for Choosing the Right Hydraulic Lift Platform

Determining the following factors will help you choose the most suitable hydraulic lift platform:

Load capacity

The maximum load capacity of the hydraulic lifting platform can be estimated according to the maximum weight of the cargo that needs to be carried.

Installation space

The width and depth of the specific location where the hydraulic lifting platform needs to be installed can be measured to determine the size of the installation space.

Platform size

The size of the platform that needs to be customized can be calculated by estimating the size of the goods that need to be carried. Our company will recommend the most suitable platform size based on the estimating platform size, installation space size, and maximum load requirements.

Lifting height

The lifting height can be determined according to the height at which the hydraulic lifting platform needs to move the cargo from one plane to another.

Power supply

Based on the conditions at the job site, what kind of power supply do you need? Direct access to single-phase electricity, two-phase electricity, three-phase electricity, or manual pump, diesel engine, battery DC, gasoline engine, generator, battery? If it is connected directly to the electricity, what is the voltage?

Exterior color

What color do you need to spray it for? Whether need to add your company's logo?

Frequently Asked Questions

10 Things You Must Know about Scissor Lifts before purchasing

At present, the maximum loading capacity of our lifting platforms can reach 30 tons, and various lifting platforms can be customized according to the customer requirements.

At present, the maximum rising height of our lifting platform can be 30 meters.

Direct access to single-phase power, two-phase power, need be determined in advance of the voltage.

It depends on what lifting capacity and what platform size you want? Basing on the lifting capacity and platform size, we will advise the most suitable installation space.

The hydraulic lifting platform is equipped with:

Relief valve: It can prevent the system pressure from being too high during upward movement.

Emergency manual valve: When the power fails, it can make the platform drop down to the nearest floor and leveling.

Manual pump: When the system fails, the manual pump can be operated to pump out high-pressure oil to raise the platform to the nearest floor.

Pipeline rupture valve: When the hydraulic system pipeline ruptures and the platform stalls and descends, it can automatically cut off the oil circuit to stop the descent.

Fuel tank oil temperature protection: When the oil temperature in the fuel tank exceeds the standard setting value, the oil temperature protection device generates a signal to stop the platform to use, it can be started only after the oil temperature drops.

Emergency stop button: In case of emergency, the platform can be stopped in time.

Safety device to prevent overloading: If the loaded goods exceed the set maximum carrying capacity, the platform will not operate normally until the normal carrying capacity is restored.

Multiple limit switch protection, door opening power failure protection device: prevent accidents caused by wrong operation.

Leakage protection device: prevent accidents such as leakage.

The standard warranty period of the hydraulic lift platform is 12 months after delivery from the factory. Except for damage caused by human misuse and force majeure, we will provide timely after-sales service.

The platform size of the hydraulic lift platform can be customized according to your working space size, please contact our company for details, our technology will give the most suitable solution with the highest performance ratio.

A high-quality hydraulic lift platform, if maintained and used properly, will run for 10 to 15 years without any problems.

The lifting speed of the hydraulic lift platform is 4-10 meters per minute.

Because the prices of hydraulic lift platform depends on the different lifting heights, and different loads, different size etc., it is recommended that you send us your specific needs, and we will send you the best quotation within 1 working day.